22 |

Oilfield Technology

May/June 2020

Additionally, purposeful gas extraction and detection programmes

help better understand gas oil ratio across the field and between

different producing formations. Applying rigorous QA-QC standards

(gas while drilling [GWD] methodology proposed by Total, Eni and

others in the late 1990s) ensures optimal data quality. Wide spectrum

measurements such as mass spectrometry provides C1 – C10 alkanes,

aromatics and inert gases. Understanding the relative relationship of

alkanes and aromatics provides invaluable insight into water saturations

that can pose a serious risk for optimal completions and production.

DatafeedsAI software

By partnering with Enovate A.I., Diversified Well Logging has been able

to add the important components of machine learning, deep learning

and AI. Taking both a drilling and geologic data driven approach is key

in order to provide success and value to clients. With an augmented

data set drilling inefficiency and associated NPT can also be reduced,

as areas for improving drilling rates can be identified and corrected in

real time (Figure 5).

Using historical production data and information, production

forecasts based on different completion scenarios forecast optimise

completions, production flow rate, decline rate and total cumulative

production. This can be done in near real time. Working with

interdisciplinary teams of geologists, drilling, completion, and reservoir

engineers as well as management, lean solutions can be provided

to improve decision-making at the drill bit, in addition to improving

planning placement, timing and spacing decisions on future wells.

The future is robotic

The company is actively working on bringing ‘robots’ to the oilfield.

Image recognition software can characterise the colour, size, and shape

of drill cuttings, allowing greater precision in gathering important

information used to minimise drilling dysfunction and the possibility of

stuck pipe due to hole instability.

Furthermore, the automated drill cutting collection and analysis

system, the ‘Robologger’, has delivered encouraging initial results. The

system delivers more consistent sample collection 24/7, regardless

of the weather and analysis samples, every 2 minutes, providing

quantitative rock composition at greater depth resolution than a

person can achieve. It lowers health, safety and environmental (HSE)

risk, reduces the carbon footprint and significantly reduces geological,

drilling, and completion risk.

As a ‘robotics as a service’ (RAAS) system, Robologger is designed

to provide a step-change in analysing the subsurface and help guide oil

and gas companies to drill with greater levels of safety and efficiency.

The additional high-resolution geological information delivered will

enhance well productivity and improve critical decision-making for

well placement and spacing (Figure 6).

Conclusion

Historically, reducing geologic uncertainty increased cost

and operational risk through larger and more expensive data

collection programs: programs that only made data available weeks

or months after the well was drilled. Today, to drive capital efficiency,

all but the most basic geological data collection programs have

been cancelled.

However, geological complexity and uncertainty still

exist. Robotics and AI provide new ways to ‘bridge the gap’ of

geological knowledge, building on the surprisingly large and diverse

data sets from surface measurements. Robotics and automation

allow the delivery of geologic certainty on every well and continuously

update models and algorithms to provide the means to decrease risk,

drive efficiency, and shape the future of the industry.

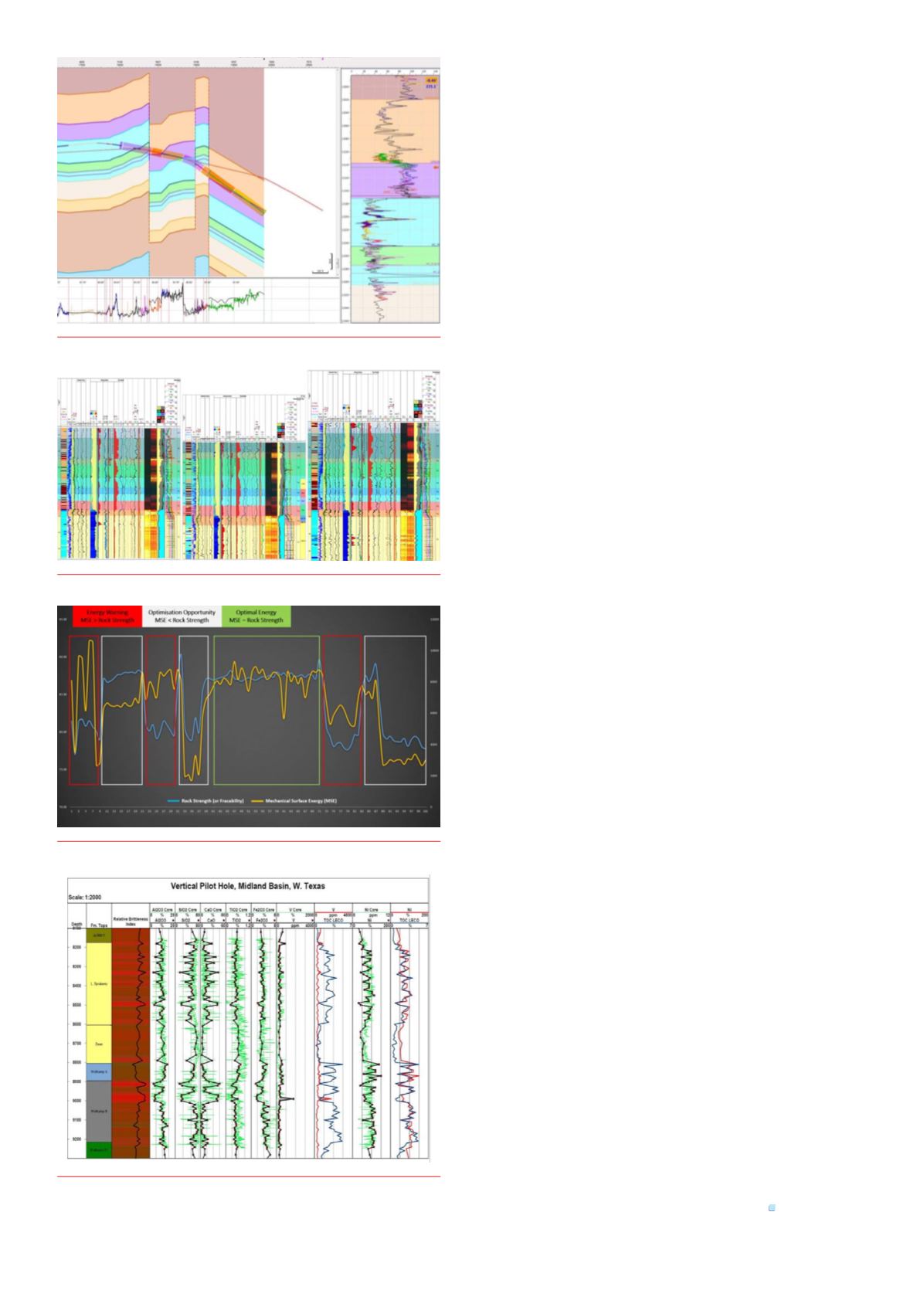

Figure 3.

HML elemental steering identifies fault GR couldmiss.

Figure 4.

Quantitative geological data improveswell towell correlation.

Figure 5.

AI software uses data to optimise drilling efficiency.

Figure 6.

Robologger drill cuttings analysedwith XRF and compared to

aCore LithoScanner.