20 |

Oilfield Technology

May/June 2020

In real time this data is used for:

Ì

Quantitative formation evaluation and correlation.

Ì

Geosteering (or elemental steering).

Ì

Avoiding drilling inefficiency and non-productive time (NPT).

Ì

Optimising landing targets.

Therefore, capital efficiency is driven by the ability to provide

high-tech low cost, high-value low risk information that would

otherwise not be available.

HML provides real time QA-QC of the samples and data. Problems

with lag depth and sample representation and contamination can

be resolved immediately rather than weeks or months later. Similar

laboratory-based services may provide data much later and at

higher cost. Real time analysis also reduces the risk of mislabelling, as

well as incorrect transport and storage of samples.

Qualityandtruth indata

Data quality starts at the rig site with trained field personnel

supported by experienced laboratory staff providing set-up, ongoing

quality assurance, and training. Instrument performance is regularly

monitored using certified geological reference materials from the

US Geological Survey (USGS) and National Institute of Standards and

Testing (NIST). Additional daily QA-QC and interpretation is performed

by experts in XRF, laser-induced breakdown spectroscopy (LIBS) and

chemostratigraphy.

Depth control is a very important part of the quality process.

Knowing that the samples are from the correct depth is a common

concern for geologists and drilling engineers. Continuous comparison

of EGR to downhole gamma ray (GR) provides confirmation the

samples are on-depth. When coherence is poor, the cause is

investigated and remediated in real time. This ensures additional

analysis such as X-ray diffraction (XRD) and pyrolysis are performed on

samples which are on-depth, represent the interval drilled and have a

known degree of contamination (Figure 2).

Furthermore, in a recent case study, as the EGR was available in

real time, it allowed a West Texas operator to utilise the information

to keep drilling when the downhole GR tool failed, resulting in

considerable savings in NPT by avoiding an unnecessary trip.

Datadrivendrillingandcompletionefficiency

Elemental and drilling field data is streamed into a real time operations

centre in Canonsburg, Pennsylvania, US, where geoscientists and

geosteerers integrate downhole and surface measurements to ensure

the wells are steered precisely and accurately within target windows.

Geosteering by GR alone may have a higher degree of uncertainty.

The integration of elemental markers greatly reduces uncertainty

and highlights important chemostratigraphic changes that GR alone

cannot.

Using HML data and smarter software, a South Texas operator

was able to successfully GeoStop a well which faulted 200 ft out

of the Austin Chalk into the overlying Anacacho Formation. The

magnitude of the fault and formation dip after the fault determined it

was not possible to steer the wellbore back into the target before the

planned total depth of the well. With average drilling and completion

costs in this area estimated to be in the US$8 – US$10 million range,

considerable savings were realised (Figure 3).

Quantitative elemental data combined with AI prompted

another South Texas operator to radically re-evaluate its mud logging

programme. One well per pad was standard practice using traditional

mud logging. Following a trial of HML, the operator found it was able

to predict hydraulic fracturing efficiency without the cost and time

of running micro-seismic and fibre-optic measurements. The power

and utility of quantitative geological data combined with innovative

software led the operator to deploy HML on all wells in South Texas for

2020 (Figure 4).

Quantitativesurfacederivedgeological data

enhancesAI

A vast amount of information can be garnered from rocks and gas

collected at the surface while drilling. XRF elemental data is used to

model mineralogy, TOC, matrix density, and estimate parameters such

as bulk density and porosity. This can be achieved without the cost and

risk inherent with downhole tools, resulting in potential savings in the

range of US$500 000 – US$5 million. The global cost of losing tools and

hole stability NPT runs into billions of dollars annually.

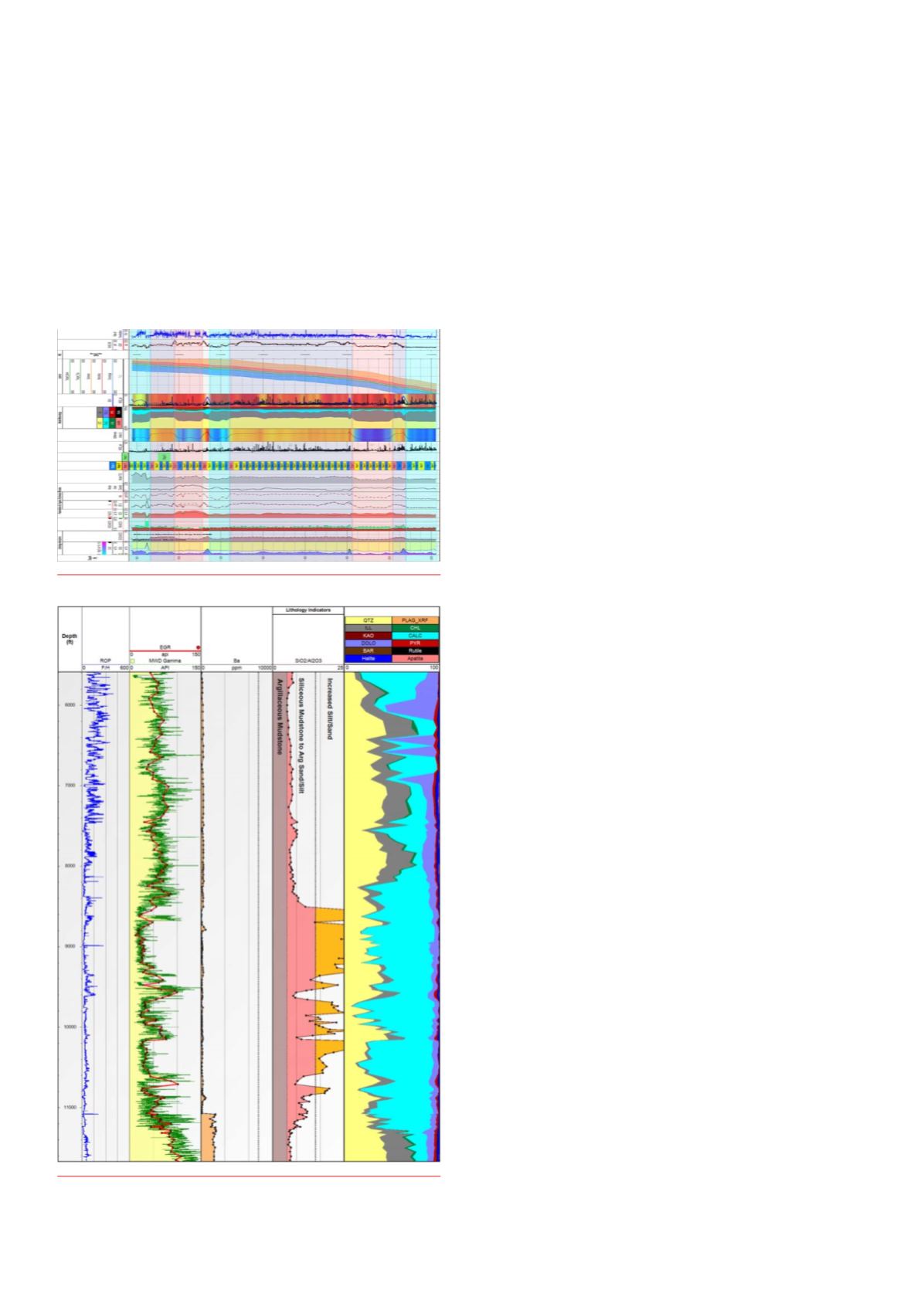

Figure 1.

Near real time data feeds engineered completions designs.

Figure 2.

GR vs EGR shows good on-depth samplingandBa

concentration shows acceptable contamination levels.