26 |

Oilfield Technology

May/June 2020

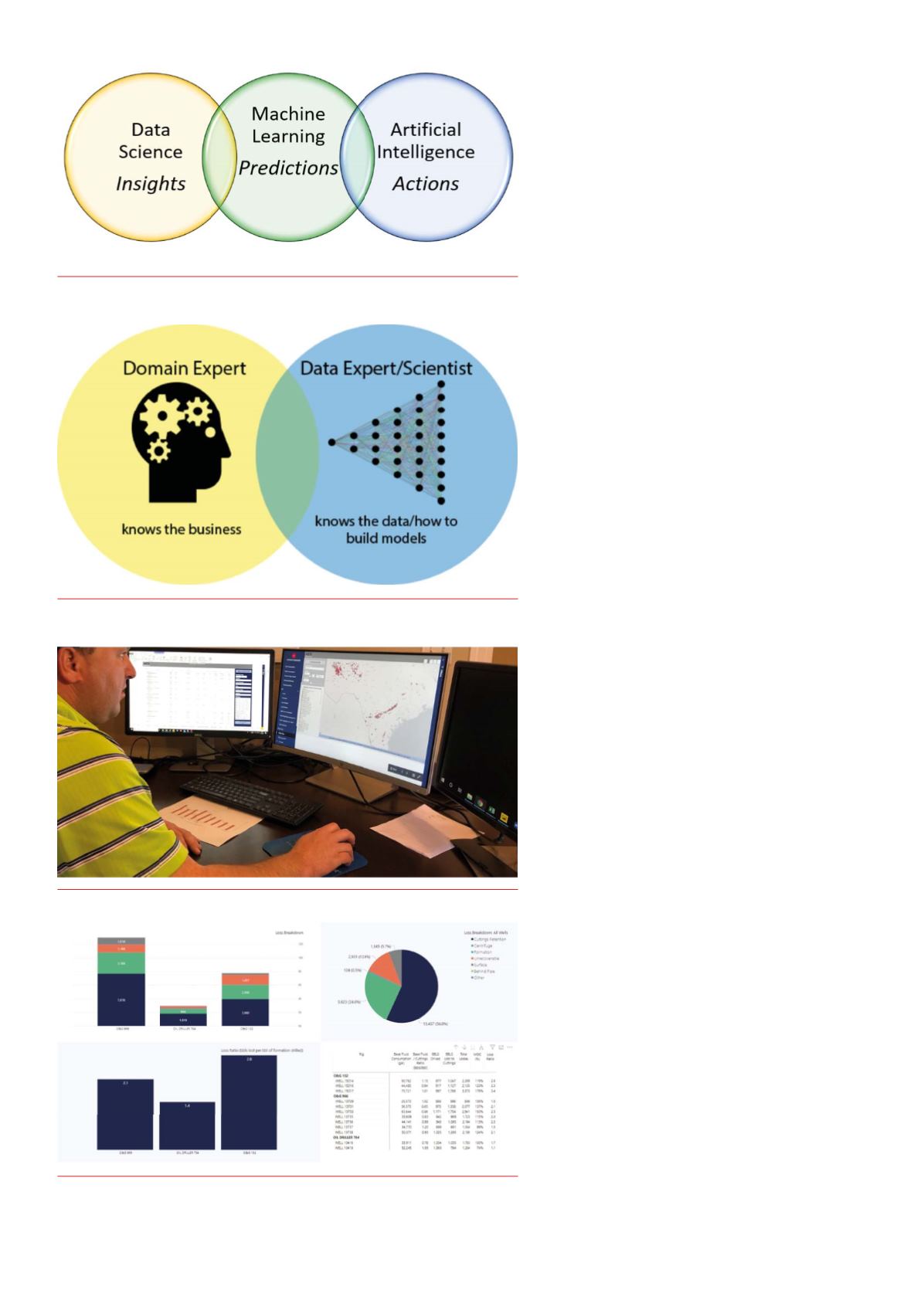

The problem lies in the overly generalised promises of data

tools. The data tools delivering real value today originate from

small, specific tasks, and expand their scope as these niche

applications deliver results. The transformation is not only

centred around data, but also a cultural shift and understanding

thatmany time-consuming tasks can be simplified through a

newapproach.

Introducing data tools that start with an initial area of focus

not only avoids ‘mission creep’, it also unites a small group of

data scientists and domain experts through the establishing of

an achievable task (Figure 2). Domain experts are essential to

defining the need and evaluating the utility of the deliverables

provided by data scientists. In ideal cases, the domain expert

also acts as the data scientist tomake the toolset as useful as

possible for their day-to-day role.

Byway of example, using the analogy of self-driving

automobile technology, an experienced data scientist who has

a limited understanding of fundamental automobile designs

and conceptswill fall short of developing an impactful analytics

platformwithout the input of their domain expert counterpart.

Analyticsplatformdevelopment

For the development of AES ANALYTICS, a drilling fluid data

analytics platformdesigned by AESDrilling Fluids, account

managers and field specialistsworked directlywith data

scientists, including thosewith field experience, to develop the

initial toolkit. A key differentiator fromgeneral data analytics

tools is that whilemany of these can report on the best drilling

fluid properties, an expert-driven platformoffers insight into the

lowest-costmeans to achieve andmaintain these best-practice

properties.

The foundational data tools of the platformwere built from

fluid reports, in particular comprehensive drilling fluid recaps

generated at the end of thewell. These data sets are regularly

reviewed as offset information to improve upon performance

drilling futurewells. Furthermore, customers regularly ask for

data sets to evaluate their own performance. Key performance

indicators (KPIs), such as cost, performance, and drilling fluid

properties, are reviewed on a quarterly basis.

Historically, this datawas gatheredmanually or through

database queries in advance of planning or reviewmeetings.

This time-consuming, repetitive task took personnel away from

monitoring activity and identifying best-in-class performance

criteria for the customer. Data analyticswas a clear opportunity

to answer the same questions through the click of amouse.

The platform’s first dashboards focused on answering the

most common questions for well planning and KPI meetings

(Figure 3). Topics includedmudweights, drilling fluid losses,

product consumption, cost vs days, and comparisons between

drilling rigs (Figure 4).

Clear visualisations and the ability to investigate interesting

data points by sliding or clicking on a graph provides access to

information quickly, but it also reveals erroneous or incomplete

data. Over the years, errors can accumulate and require a

thorough quality control review. A substantial amount of the

initial work centred around verifying data sets.

With a validated data structure, the platformwas

slowly deployed to customers and accountmanagers. An

email account was set up to address any errors and for new

feature requests. The customer dashboards, centring around

KPI metrics, weremade available through an individual,

unique login. The ability to expand the technology from its core

Figure 1.

Comparisonbetweendata science, machine learning, and AI.

Figure 2.

Collaborative overlapneeded for domain experts anddata

experts/data scientists.

Figure 3.

Accountmanager utilising AES Analytics for an upcomingKPI meeting.

Figure 4.

Dashboard visualisation comparingdrilling fluid losses across 12wells drilled

by 3 rigs.