46 |

Oilfield Technology

May/June 2020

Casestudy:DelawareBasin,US

Delaware Basin and Arkoma Woodford formations have proved to

be challenging drilling environments. Customer A was running the

curve-lateral in the Delaware Basin, Reeves County. Their 6 3/4 in. bit,

outfitted with a thermally stable PDC, drilled approximately 9000 ft of

Wolfcamp A curve-lateral. The bit landed the curve and proceeded to

drill an additional 8000 ft, reaching total depth (TD) in 170 hours and

was dull graded at 1-2-CT-S-X-IN-NO-TD (Figure 2).

Casestudy:Oklahoma,US

Customer B was running the Woodford lateral in Hughes County,

Oklahoma. Their 8 3/4 in. bit drilled over 10 000 ft, averaged over

3800 ft/d at a rate of 160 ft/hr and increased rate of penetration (ROP)

by 23% over their previous record (Figure 3).

Productdevelopment

With the ever-changing financial stresses in the market, it is essential

to develop a product that will not only perform but also delivers value

for the consumer. Collaboration with numerous companies has yielded

knowledge from field data and a greater understanding of how the

PDC performs downhole. After collecting, analysing, and evaluating

the field data, a second generation of products has been developed:

All-Terrain, Tactical, and Elite. These series utilised the company’s latest

technology in order to provide an enhanced, customisable PDC to

cover multiple facets of hard-to-drill environments.

The All-Terrain series, with an updated press sintering method, is

designed to tackle three key performance aspects: thermal, abrasion,

and impact. The balance between these three characteristics is crucial

to determining how the products in this series perform downhole.

The design concept behind the Tactical series was to develop

products that are focused on specific performance requirements for

niche drilling environments. Some cases require a cutter with more

thermal stability, while others require a higher abrasion resistance

cutter. Depending on the application, this range emphasises specific

aspects of those thermal, abrasion, or impact resistance needs.

The Elite series was designed with an updated press method.

Performance was improved based on numerous results from extensive

Instron and VTL testing. This enabled the development of a product

that has a higher resistance to thermal degradation, crack expansion

and crack propagation, along with improved interfacial stress relief.

Leaching

PDC leaching technology is used to provide improved thermal

stability in cutter performance by removal of catalyst material. This

is critical to product performance downhole. Over the last 15 years,

IDS has tested, developed, and implemented a method to remove

catalyst metal: metals are removed from the sintered diamond layer

at depths exceeding 1000 micro, and a proprietary masking technique

maintains the substrates’ structural integrity. Non-destructive testing

methods ensure accurate measurements of leach depth that conform

to individual customers’ needs.

Outside of the PDC realm, the company manufactures newly

designed diamond-impregnated inserts, with the capabilities/abilities

to supply coated and non-coated TSPs and a variety of synthetic and

natural diamond stones for various applications.

Conclusion

The industry continues to discover numerous techniques that

enhance the overall performance of a drill bit. Products are being

manufactured that can individually target a customer’s drilling needs

for thermal, abrasion, or impact resistant cutters and subsequently

improve drill bit performance in the field.

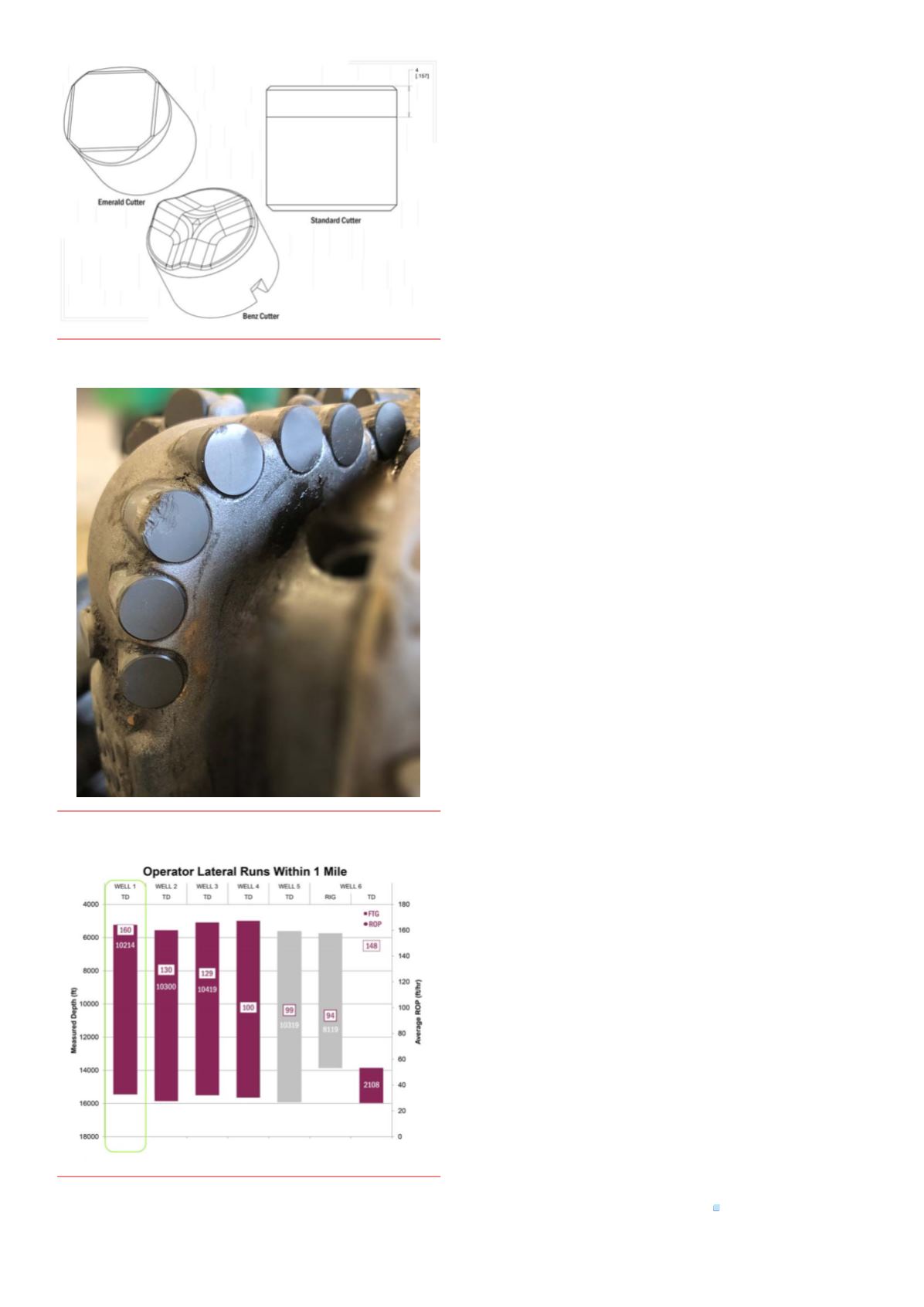

Figure 2.

A 6 3/4 in. bit usedby a customer in theDelawareBasin showed

minimal PDC cutter wear when utilisinga thermally stable PDC.

Figure 1.

Deep leached, thermally stable andwear resistant cutters are

designed to operate in challengingdrilling environments.

Figure 3.

The chart outlines the previous run comparisons froma

customer operating in the ArkomaWoodford lateral.