42 |

Oilfield Technology

May/June 2020

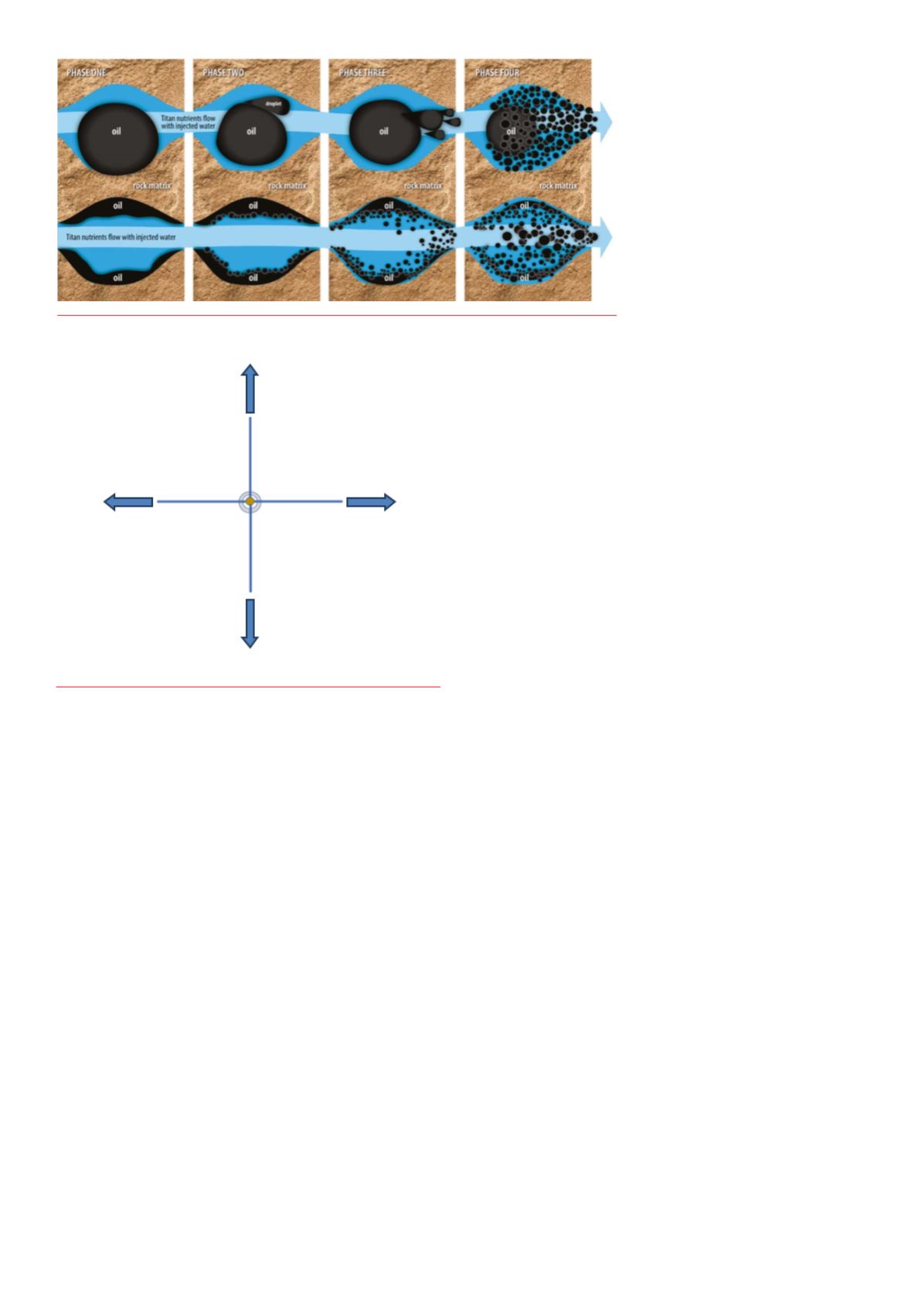

Organic Oil Recovery® (OOR) is currently being promoted

by Hunting Energy Services in 23 countries in cooperation with

Titan Oil Recovery. The technology uses tiny micro-organisms to

release oil trapped in reservoirs. These are called microbes, which

are so small a tablespoon of garden soil contains 1 trillion microbes.

Certain species live in the oil reservoirs with no oxygen. OOR

technology allows the microbes to surround oil globules trapped

in the reservoir pore spaces, and deform the droplets into micro oil

droplets so that they can then escape the pore spaces they were

trapped in (Figure 1). This is achieved by sending nutrients into

the reservoir to feed only certain species of microbes. The current

nutrient delivery system used by Titan could be enhanced even

further with smallbore lateral drilling.

The seldom-used smallbore lateral drilling (often referred to as

‘spaghetti string’) technology has yet to find a ‘killer application’

for its different drilling approach. Essentially, it comprises a

small diameter coil tubing enhanced drilling technology that

takes a conventional vertical oil well, places a small diameter

(1 in.) drilling unit downhole and redirects a smallbore hole

horizontally within the pay matrix. This is repeated in four directions

(Figure 2).

One can see from Figure 2 that the communication from the

wellbore to the reservoir fluids consists of a small area along the

wellbore that would be perforated for the length of the zone that

is being accessed. The original low pressure zone is represented

by the small circle where the reservoir

fluids would be flowing towards the

wellbore. With the small lateral holes

now extending out from the wellbore,

four new and considerably extended

low pressure zones have been created,

allowing reservoir fluids to be taken into

the new lateral boreholes.

In the past, the problem with this

drilling technology was that trapped

oil only 1 cm from the new lateral

borehole could not move into the lateral

borehole: it was trapped oil. With the

OOR nutrients (represented by the gold

arrows in Figure 3) now being pushed

out in four directions and in a cone-like

manner, the reservoir matrix – having been saturated with the OOR

nutrients – is increased significantly and that area contains microbes

that should respond to the nutrients and release trapped oil.

Due to the fact that the drill string and cutting tool is so small the

resistance from the rock is consequently reduced. Boring through

rock with 5 – 10 in. dia. drill bits is considerably harder and more

expensive than using a 1 in. dia. drill bit.

The concept behind the spaghetti laterals was to contact oil

away from the wellbore, bypass wellbore damage and create

multiple low pressure zones away from the wellbore. However, as

stated earlier, trapped oil was still a problem. If the small laterals

could be used with the OOR technology and so release trapped

oil, then the delivery system of the OOR nutrients would change

from a one-dimension point outward from the vertical wellbore

perforations to a four-dimensional process extended out horizontally

in four directions from the wellbore (Figure 3 shows the red arrows

extending out in two directions).

Although Titan’s OOR technology is ideal for water-flooded

fields, single well applications with a huff and puff method have

proven successful.

The new lateral holes – by creating new multiple and extended

low pressure zones – could allow for better pore space drainage from

the existing reservoir pressure, combined with the micro oil droplet

effect of the process. Radial drilling can also be applied to injection

wells and offshore.

Considering that 65% of the oil surrounding these wells

is trapped and OOR already releases substantial amounts of

incremental oil, this new delivery system for the process could allow

for even better recovery factors and production volumes in vertical

oil wells.

The OOR technology is an EOR technology that manages the

biology and ecology of an oil reservoir and feeds certain microbial

species a special nutrient package that results in the microbial

species multiplying dramatically, and then creating a phenomenon

that releases trapped oil from the pore space of the reservoir.

The current huff and puff method allows for the OOR nutrients

to be pushed or squeezed out into the formation and for the

microbial reactions to take place in that area. Due to certain physics

and chemical phenomenon, the nutrients diffuse out away from

the wellbore and affect an increased areal matrix. However, if the

nutrients could be displaced even further from the wellbore then a

significantly larger area of the oil-producing zone could be flooded

with the nutrients and this could create an even larger oil production

response (Figure 3).

OOR could be a useful technology in the smallbore (spaghetti

string) lateral drilling industry.

Figure 1.

Simple diagramof howOOR createsmicro oil droplets.

Figure 2.

Small lateral drill holes are nowextended out fromthe

wellbore.