38 |

Oilfield Technology

May/June 2020

Prior to commencement of well control operations, a significant

amount of dredging had to be completed to provide barge access to

the well, as the waterway leading to the rig was too shallow otherwise.

Initialwellheadassessment

Ignited flow could be observed escaping from the side outlet valve on

the B-section of the wellhead (2 7/8 in. tubing x 9 5/8 in. casing), sending

a strong hydrocarbon stream upwards and outwards, and to a lesser

extent downwards. Minor leaks were observed between the top of the

B section and the tree, and also near the top of the upper master valve.

It was unknown at the time whether the plugs in the tubing or any of

the packers had failed, which would have led to either an annular leak

path through a damaged packer or through a more complex route

involving tubing leaks.

Interventionstrategy

As several barriers had been installed in the tubing, it was determined

that annular flow through a damaged packer was the means by which

the hydrocarbons were leaking. It became clear that the initial thrust of

the recovery operations would entail tree removal.

After removing the lower flange of the B section, the upper

13 5/8 in. wellhead flange condition could be inspected. The subsequent

sequence of steps to control the well would ultimately depend on the

results of the inspection. If the existing wellhead flange was found to

be damaged, the entire wellhead would have to be cut off to allow

re-heading. Unfortunately, re-heading would require the installation

of a coffer dam because the wellhead was below the water level at

high tide.

If the existing wellhead flange was found to be serviceable

however, capping could be performed on the existing flange using a

capping stack.

A third option for well control was to use a relief well to stop the

flow of hydrocarbons.

Mobilisationofpersonnel andequipment

Boots & Coots specialists were initially dispatched to the operator’s

base to help generate planning documents and to liaise with company

personnel working from the operator’s camp to guide preparations and

coordinate planning with the operator’s office.

Coordination of the sourcing and mobilisation of specialised

firefighting equipment available in-country was also carried out.

Firefighting equipment, including an abrasive jet cutter available

in-country, were transported to the dock facilities and loaded onto

the barges for transportation to the staging location. On arrival, the

equipment was reassembled, tied down and tested prior to being

transported to the field. The equipment included:

Ì

A pumping barge.

Ì

A firefighting barge.

Ì

An Athey wagon barge.

Ì

A crane barge.

Ì

A spare barge.

Ì

A lube and bleed barge.

Additional firefighting equipment was mobilised fromHouston to

ensure sufficient backup was available.

Sitepreparation

Extensive dredging was required to facilitate work barge access to the

well area. The prevailing wind direction was from the southwest and

carried gas and residue across the canal entry and across the main

canal towards the local communities. Available barges were sourced

and modified to suit the planned operations and the operator was also

assisted in procuring the required heavy equipment and materials,

using knowledge of in-country vendors.

The logistical challenges of maintaining operational support

routes, continuous fuel provision, and security concerns were dealt

with on a daily basis. Tidal influences within the well estuary limited

the ability to conduct necessary civil work, as the outgoing tide

pulled surface oil back towards the canal, creating an impassable

burning curtain. After four weeks, the well began to produce water

in sufficient amounts to temporarily extinguish the well fire. With

each extinguishment event, the well flowed significant amounts of

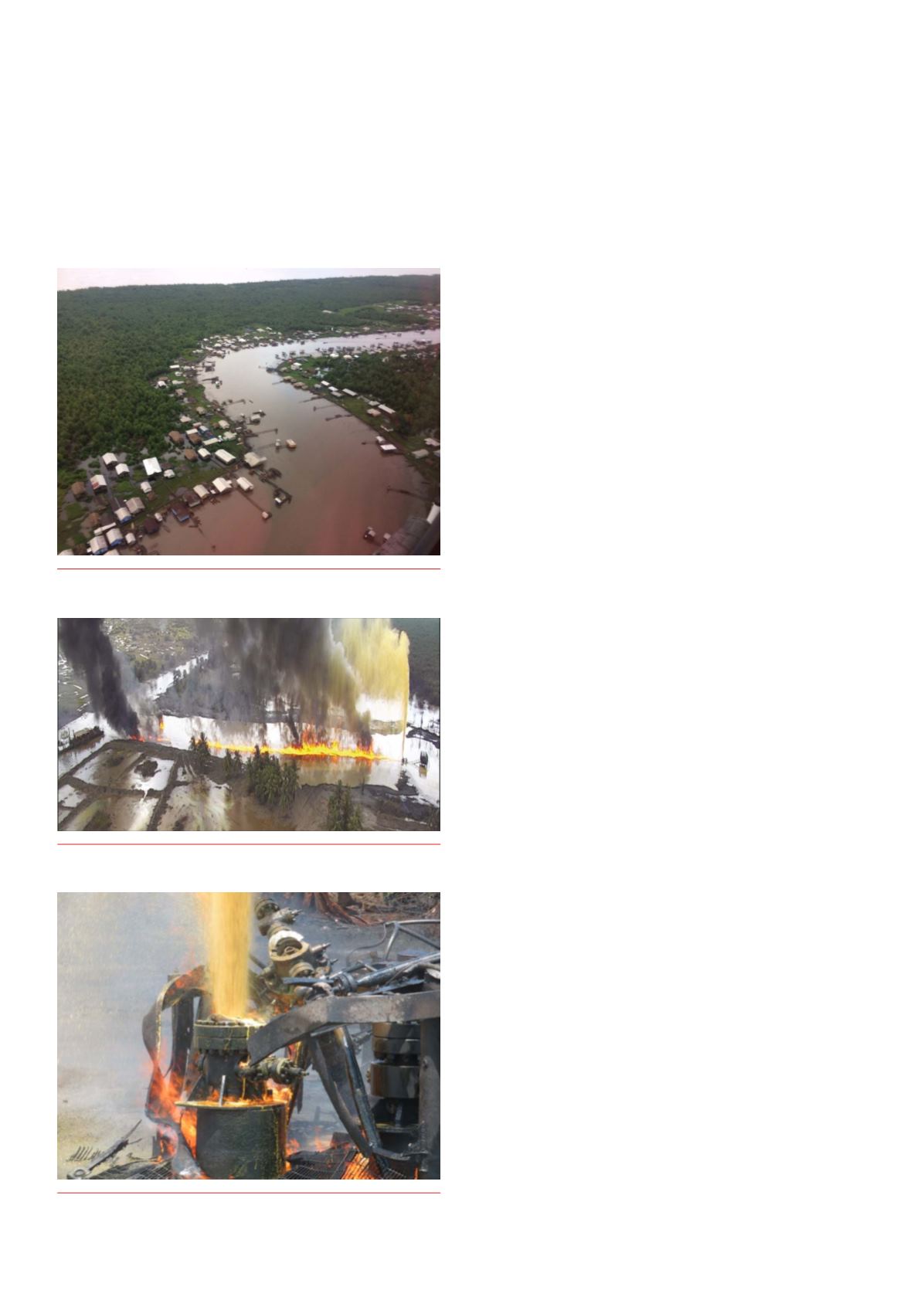

Figure 1.

Riverside fishing communities along the estuary access to the

wellsite.

Figure 2.

Hydrocarbons spillingalong the estuary fromthe blowout well

and spontaneously igniting.

Figure 3.

Well blowing vertically.