May/June 2020

Oilfield Technology

|

39

combustible oil onto the water surface and into the surrounding

vegetation. This created significantly larger surface fires each time the

well spontaneously reignited.

Shallow dredging to expedite access to the well resulted in barges

and work boats being stranded and exposed to surface oil fires due to

changes of wind direction.

Well control operations

Structural members of the well jacket initially limited access to the

wellhead. Consequently, vertical members on the northwest and

northeast corners of the well jacket and a horizontal member of the

jacket that were blocking access from the north side of the well were

targeted for removal by the abrasive jet cutter.

The Athey wagon barge was equipped with the rake attachment to

attempt removal of these structural members. The firefighting barge

was spotted on the west side of the slot to allow the Athey wagon barge

to move into the well on the east side of the slot. In the event, the tree

could not be pulled away by the rake, which meant it had to be cut

off using an abrasive jet cutter. Water monitors sprayed the wellhead

to suppress the fire and heat, allowing the well control specialists

to approach the well and assess and identify which structural

components of the well jacket would have to be removed in order to

enable the jet cutter to carry out the cutting operation.

Wind and tide conditions delayed several efforts to remove

additional debris; a total of six cuts were made by Boots & Coots, using

an Oxylance and an acetylene torch, to remove additional debris from

the northwest side of the well jacket in preparation for removal of the

lower B section flange and well capping.

The abrasive jet cutter successfully removed the tree at the

B section, leaving the 13 5/8 in. lower flange of the B section still

attached to the upper flange of the wellhead (A section).

Using fire cannon water spray, the abrasive jet cutter was used to

cut the tree off as planned, resulting in a single vertical flow from the

well (Figure 3).

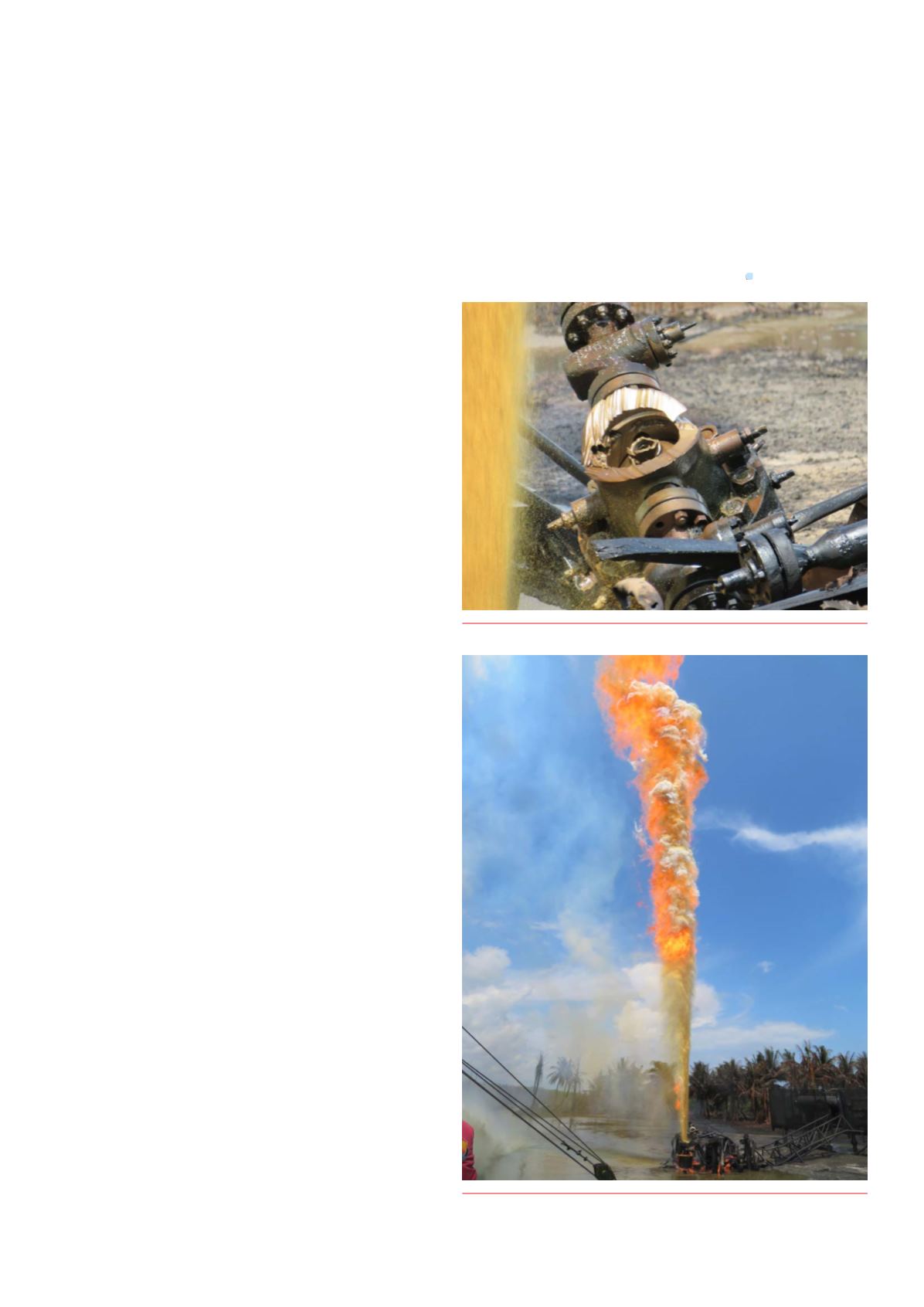

Close inspection of the 13 5/8 in. wellhead flange condition

indicated it was still in good enough condition and that capping could

be performed (Figure 4).

The action of removing the tree prevented the lateral extension of

the fire and greatly improved both visibility and safety by directing the

flame upwards (Figure 5).

A venturi tube was installed above the casing head to direct the fire

vertically and away from the area while working on preparations for

the installation of the capping stack.

Cappingstack:designandassembly

The company designed and constructed a capping stack using blowout

preventer (BOP) equipment available from the operator and in-country

resources. The stack was assembled, tested, and transported on a

barge to the well staging area. A yoke was designed and constructed to

support the stack using the Athey wagon boom, in order to deploy the

capping stack onto the well. Inclement weather and tidal conditions

delayed the proposed capping operations for a number of days as

approximately 10 daylight hours of favourable tides and wind direction

was required. At this point, the operator decided to continue the

capping operation with its own personnel.

Importantly, difficulty in sourcing the necessary double-studded

adaptors resulted in the use of a modified B section to cross over from

13 5/8 in. 3M to 11 in. 5M at the bottom of the capping stack.

Summary

The well was successfully addressed through a coordinated project

that used a number of barges in a particularly difficult environment.

Although much of the equipment required could be mobilised

in-country, significant time had to be dedicated to both sourcing

the necessary vessels to transport the equipment and the dredging

operation to gain access to the rig site. The particularly challenging

operation of debris clearance – in order to gain access to the

wellhead – took considerable time, but was safely and successfully

accomplished, as was the planning and cutting of the wellhead in

preparation for the newly engineered capping stack.

Despite adverse weather conditions, the remoteness of the

location leading to a myriad of logistical challenges, and a dynamically

changing situation, the operation was conducted safely with no lost

time incidents during the wellhead remediation.

Figure 4.

Bottomof cut onB section.

Figure 5.

Removal of the tree achieveda single vertical flow.