May/June 2020

Oilfield Technology

|

33

and aligns the handled pipe with the drill string in

the rotary table, the stick-up. Removing the need

for people to work together with the machinery

here entails a potentially substantial improvement

in safety.

The combination of a hydraulic elevator, iron

roughneck and hydraulic power slips, developed

by the company, completes the full cycle of pipe

tripping. The stabbing of the pipe and making the

connection is a fully automated sequence.

In this instance, automation does not mean

the cabin masterminding operations with support

from a rig crew on the floor; it means no personnel

required on the floor, with 1800 ft/hr tripping

speeds being achieved.

For the bottomhole assembly (BHA), as for

odd-sized equipment, a procedure has been put

in place that makes use of the mast telescopic jib winch to bring

equipment from the ground level direct to the well centre or to the

mouse hole position. Although tugger winches are still installed on

the rig, dragging tools over the floor by using tugger wires is not

required for these operations.

Casingrunning

With automated tripping processes and drilling connections having

been implemented, there was still one hurdle to moving personnel

entirely out of the red zone during routine operations: the lack of

fully automated casing running.

A handler was developed that could handle tubulars

between 2 7/8 in. and 13 3/8 in., e.g. casing, collars and drill pipe.

The gripper is a one-size-fits-all design, removing the need for

manual preparation to handle the casing. The hydraulic power slips

can handle the casing and provide counter torque when making

connections in combination with the use of a casing running tool.

The precise handling and guiding ensures that the casing is handled

carefully and thread is not damaged during the process. The

integrated torque turn graph logger and controller stores for each

run the length and torque characteristics into the auto tally system.

The list is shared on an OPC server with the operator, which allows

the remote monitoring and approval of the tally list in real time

while the rig crew can focus on the safety of the casing running

process. The integrated casing running programme prevents

separate casing tongs and casing spiders needing to be rigged

up by a different casing running crew. This ‘hands-off’ process

complements the programme of safe tubular handling while

offering fast operations at 1300 ft/hr, equal to 30 casings/hr.

Such automation, in combination with the trailerised design

of all modules, results in minimal manual handling of equipment

during operations and rig moves.

Conclusion

Use of the mobile rig means that manual tripping of typical tubular

tripping is no longer necessary. In addition, the drilling operation

and standard casing running no longer require people on the drill

floor, working in the red zone. This significantly improves the safety

levels of repetitive operations on the rig, while not compromising

on performance. BHA handling and odd-sized items are now

handled safely through the introduction of the mast mounted

service jib winch.

This technology is available now for full implementation,

and the rig is scheduled to start operations for a major operator

in 2020.

Figure 5.

Operations fromthe cabin.

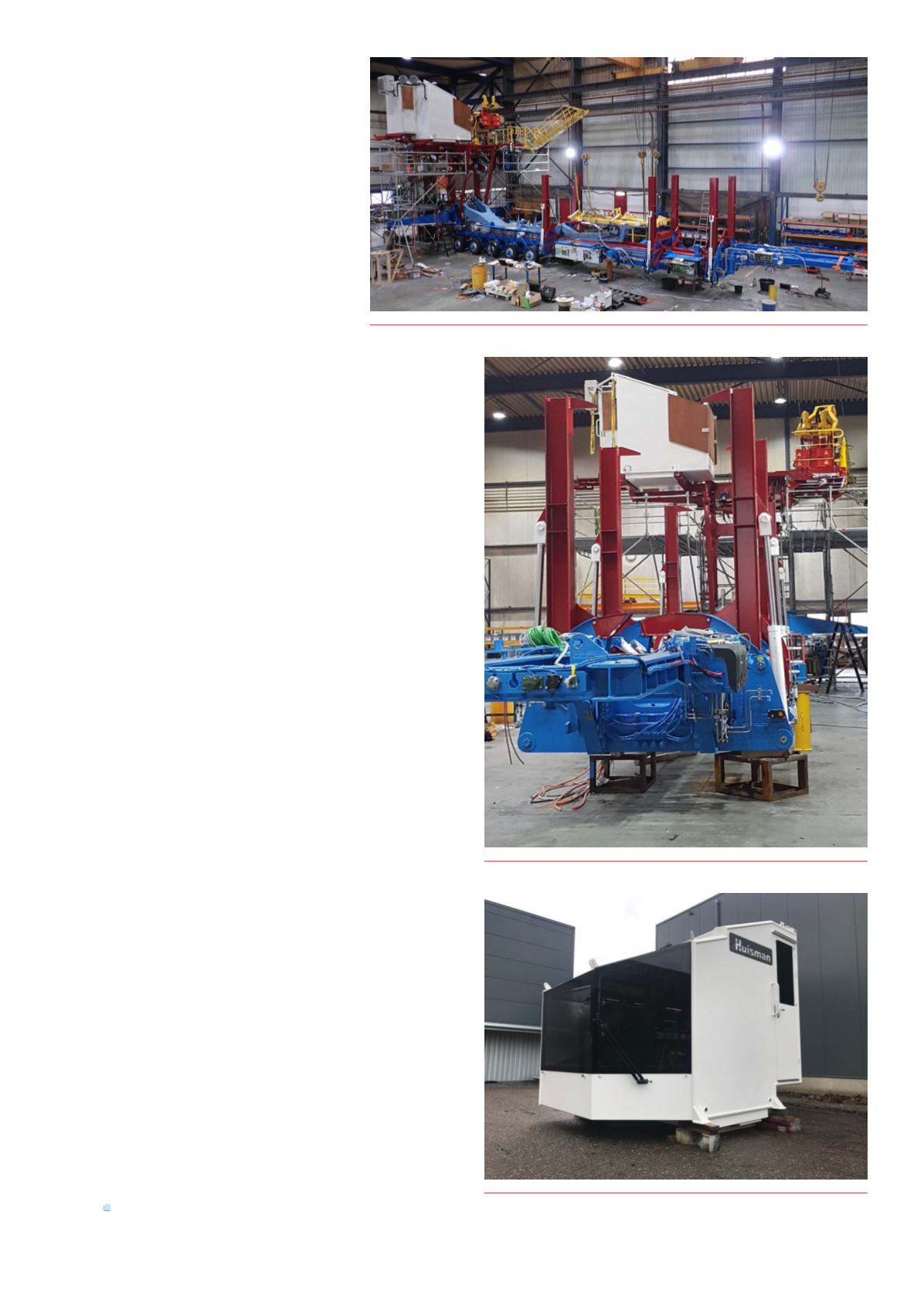

Figure 3.

The rigunder construction.

Figure 4.

The rigunder construction.